repair work with Hypalon/ csm

here is a write up, photos showing do's and don'ts when working with and preparing Hypalon/ csm fabric. when you haven't done it before it can feel very overwhelming not knowing how much is the right amount of sanding for a successful repair, here are examples to help you

smooth Hypalon

So as you probably know Hypalon has 2 sides, the coloured side(front) and the none coloured side (the back), both of which can be sanded and bonded using the correct adhesive. this is the smooth grey back version it requires sanding both sides before adhering,

Black back Hypalon

very much the same as above however this was one of the first attempt at "non buff" material, a fabric that would only need sanding on the front surface when bonding. on most of the early humber ribs they used black back material as a way of saving money, when they wanted black such as on the underneath strips they would just reverse the coloured fabric. Many came to the conclusion it was still safer to sand both sides of this fabric, it also had a tendency to fade and deteriorate quickly. this type of fabric was known as aerojor. Here is an example of sanded black back so you can see how it looks when sanded

Non Buff

this is the revised type of none buff( back/inside ) that actually works very well, it is commonly found on all orca carbon fabrics also used with many other colours and textures as well. you can thoroughly solvent wipe this then use adhesive straight on the back with no sanding required.

Carbon and textured fabric preparation

When preparing the front face of any textured Hypalon fabric it is very important to sand off the texture to a smooth matted surface. this example shows the correct amount of abrasion required for a successful bond on Orca carbon Hypalon.

sanding non buff fabric

sometimes you may prefer to sand the non buff surface here is an example of a perfectly sanded none buff fabric ready for adhesion.

sanding the front face of smooth Hypalon

here is an example of smooth fabric with the correct amount of sanding when preparing a repair, as you can see its sanded and there are no shiny areas indicated by the green circle. The red circle is unsanded and shines

burn through

here is a step guide of how it looks to sand too far through the fabric it is easily done if you are using to course grit sand paper we recommend 60grit both with the red cross will potentially leak through, certainly if the other side of this area is also sanded. the far left shows the inner weave, the part of the fabric that gives it its tensile strength. if this is damaged the fabric may rip or create a kind of hernia when inflated.

when sanding the back

when sanding the back, its important to know how much is required when it is lightly sanded it usually turns a light grew white before going darker when it is correctly sanded as indicated bellow, the green tick indicates the correct amount of sanding required for a successful repair

sanded v not sanded

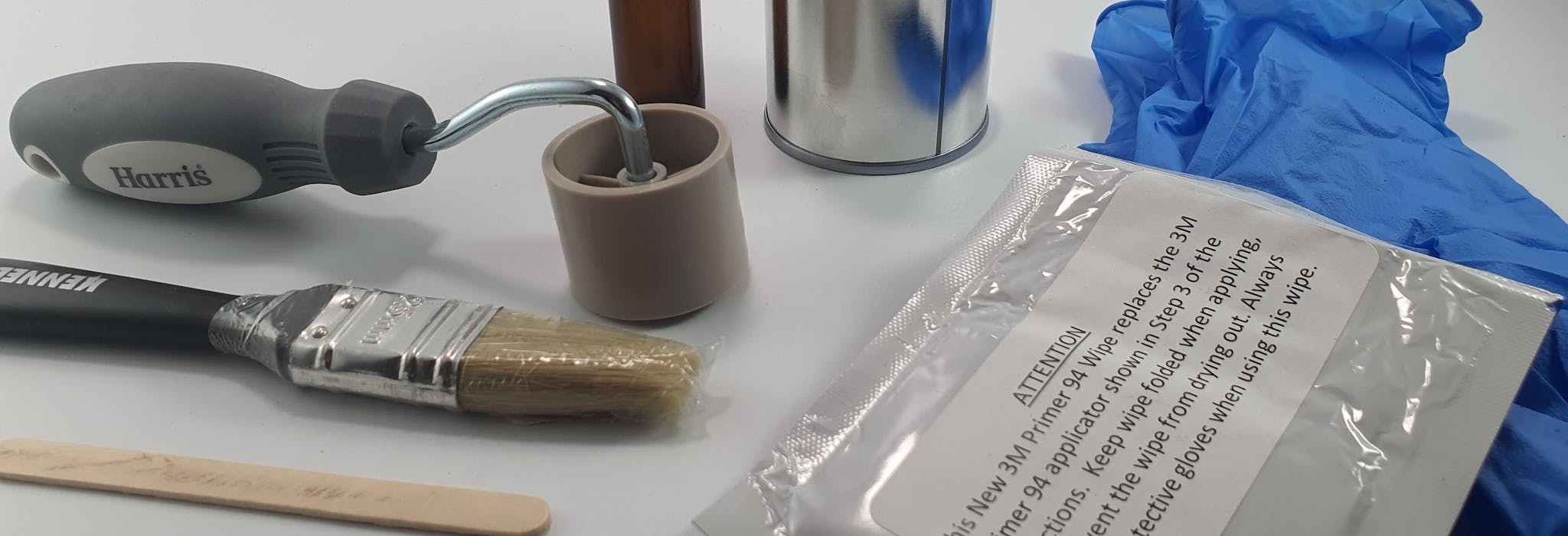

here is another example of correctly sanded fabric versus not sanded. this would be fine for wiping with solvent and applying a priming coat